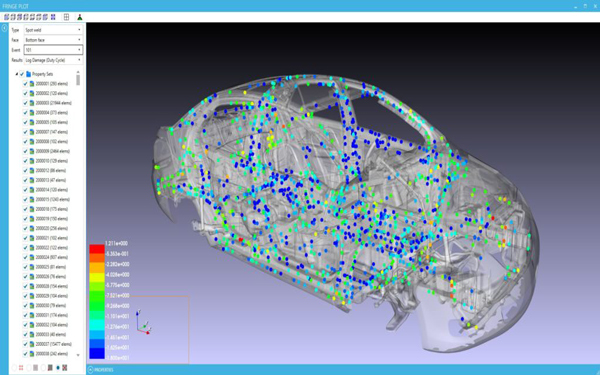

MSC CAEfatigue + Resource Pack

یک نرم افزار شبیه سازی برای کارخانه ها و کارگاه های تولیدی است که می تواند به شما مقدار استهلاک قطعات و مواد مصرفی بر روی دستگاه های کارخانه و کارگاه ها را نشان دهد . سالانه در همه جای دنیا تخمین زدن مقدار استهلاک قطعات علاوه بر وقت زیادی که می گیرد ممکن است با خطای فراوان رو به رو شود و به همین خاطر سود ناخالص به درستی برآورد نشود . گزارش ها و مقالات فراوانی نشان می دهد که تقریبا مقدار 4 درصد از سود ناخالص کارخانه ها و تولیدی ها به اشتباه تخمین زده می شود و صرف نوسازی قطعات به کار رفته و مستهلک شده می شود و اگر بتوان از ابتدا حدس زد که دستگاه ها تا چه مقدار دچار خرابی و استهلاک می شوند می توان از این مقدار کاستی در سود ناخالص جلوگیری کرد . برنامه های فراوانی وجود دارد که می توانند به شما بگویند که قطعه ای مصرفی شما در کجای آن دچار بیشتری خسارت می شود و شما به عنوان ناظر می توانید قبل از ، از کار افتادن وسیله آن را جایگزین کنید ، اما هیچ برنامه یا نرم افزاری همانند نرم افزار MSC CAEfatigue + Resource Pack وجود ندارد که به شما بگوید که این نقاط دچار چه مقدار استهلاک می شوند و تا چه مقدار عمر می کنند . این نرم افزار مهندسان ناظر را قادر می سازد تا به سرعت و با دقت پیش بینی کنند که چه مدت قطعه مورد نظر با هر نو ساختار و جنسی که دارد ، چه مدت زمان دیگری را می تواند پاسخگوی نیاز تولیدی باشد . از دیگر امکانات

نرم افزار MSC CAEfatigue + Resource Pack

می توان به : محاسبه مقدار استهلاک در هر نوع قطعه ، محاسبه پویای مقدار استهلاک در محیط CAE ، قابلیت تخمین زدن طول عمر با فن آوری جامع MSC ، تجزیه و تحلیل مقدار استهلاک و … اشاره کرد .